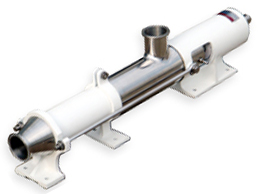

F Series

Special Features

- Stators are made of non-contaminating food grade polymers, resistant to oils, fats etc.

- All internal contours are designed to be swept by the product flow or by a detergent when “in-line” cleaning

- Elimination of product retaining pockets avoids chemical or bacteriological contamination

- Simple construction allows quick dismantling along with easy mounting joints ensures service friendliness.

- CIP (Cleaning in place) design allows for residual-free and bacteria-free cleaning.

- SIP (Sterilization in place) can be done using Superheated steam for in-process equipment

- Can work against high vacuum. Ideal for lifting viscous fluids from the vacuum pan.

- Low fluid velocities ensures gentle handling of shear sensitive fluids without damage.

- Pulsation, turbulence or aeration-free metered flow proportional to speed

- Capacity varied simple variation of pump speed to match system parameters

FAS Range Standard Hygeinic Progressive Cavity Pump:

FAS range is equipped with an open aseptic joint design that can be cleaned without residual particles through CIP continuous cleaning. The open fork joint features an especially shaped coupling rod without any contours, other than that it only contains a Pin and a Retainer spring.

Technical Parameters

Capacity: 200 Cu.M/Hr

Head: 24 Kg/sq.cm

Temperature: Up to 180 Deg C

Viscosity: Up to 50,000 CST

FAP/M/N Range Standard Hygeinic Progressive Cavity Pump:

FAP range uses a standard pin- bush joint, these are generally used for more abrasive and viscous media to reduce the wear of the joint.

Pumps are available in Bareshaft and Close-coupled Designs.

WIDE THROAT HYGEINIC PROGRESSIVE CAVITY PUMPS

The WF Series are are used primarily in the food, pharmaceutics, cosmetics and chemical industries. These pumps with CIP (Cleaning In Place) and SIP (Sterilisation In Place) capabilities meet the highest requirements for gentle handling, hygiene, cleaning and sterilization. They have a Hopper type Suction Inlet allowing gravity flow of Plastic Viscous media on a screw conveyor “Augur” which pushes the viscous media into the pumping cavity.

These pumps comply with the highest of International Sanitary Standards and. The Pumps are offered in all wetted parts being in Stainless steel with Food grade Rubber Stators.

Salient features:

- Suitable for all media up to most thick pulpy consistency with highest content of solid or fibrous material

- Open hopper type inlet with force feed screw upstream of rotor and stator

- Pulsation, turbulence or aeration free metered flow proportional to the speed

- Capable of developing up to 48 Bar even at low pump speed

- CIP (Cleaning in place) design allows for residual-free and bacteria-free cleaning.

- SIP (Sterilization in place) can be done using Superheated steam for in-process equipment

- All internal contours are designed to be swept by the product flow or by a detergent when “in-line” cleaning

- Elimination of product retaining pockets avoids chemical or bacteriological contamination

- Simple construction allows quick dismantling along with easy mounting joints ensures service friendliness.

- Low fluid velocities ensures gentle handling of shear sensitive fluids without damage.

- Capacity varied simple variation of pump speed to match system parameters

- Torsion-free metal bonded stator for increased stator life and higher efficiency per stage pressure

- Can work against high vacuum. Ideal for lifting viscous fluids from the vacuum pan.

- Pulsation, turbulence or aeration-free metered flow proportional to speed

- Special Design Add-ins:

- Shaft sealing Mechanical seals or Food grade gland packing Material

- End Connections DIN / SMS / Quick release Clamped / Equivalent end connections

- Bridge Breaker Paddle Assembly Used for products forming bridge while handling high consistency media.

- Counter Hopper Is used on top of the existing hopper to increase the holding capacity of the hopper.

Range WFS Wide Throat Hygeinic Progressive Cavity Pumps for Hygenic Applications:

WFS range is equipped with an open fork aseptic joint design that can be cleaned without residual particles through CIP continuous cleaning.

WFP/M/N Series Wide Throat Pumps for Hygenic Applications:

Hopper type suction inlet allowing gravity flow of Plastic Viscous media on a screw conveyor “Augur” which pushes the viscous media into the pumping cavity. FAP range uses a standard pin- bush joint, these are generally used for more abrasive and viscous media to reduce the wear of the joint.

Pumps are available in Bareshaft and Close-coupled Designs.

Technical Parameters

Capacity: 100 Cu.M/Hr

Head: 24 Kg/sq.cm

Temperature: Up to 150 Deg C

Viscosity: Up to 500,00,000 CST

Solids Consistency: as high as 90%